Published: July 12, 2025 | Science Desk | The Banga Enquires

What Are Bioceramics?

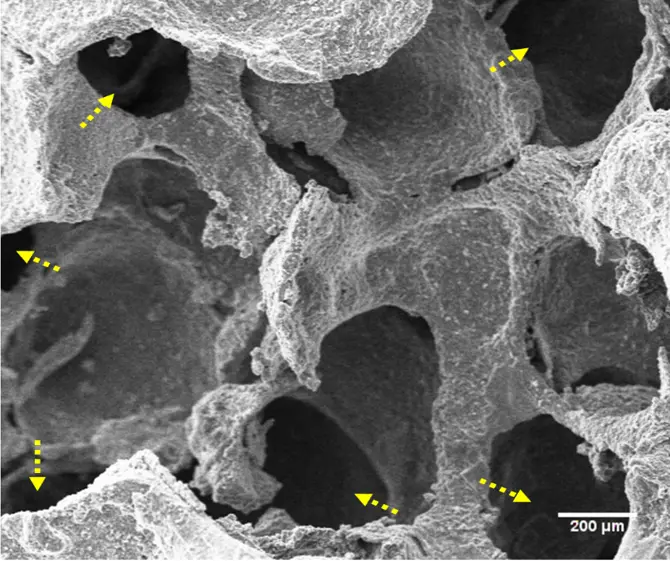

Bioceramics are advanced ceramic materials engineered for biomedical applications, particularly in bone, dental, and joint repairs. Made from compounds like hydroxyapatite, alumina, and zirconia, these materials mimic the mineral content of bone and offer excellent biocompatibility.

Unlike metals, bioceramics are non-corrosive, chemically inert, and often bioactive, meaning they not only integrate well with tissue but may actively stimulate bone regeneration.

Why Are Bioceramics Important?

With rising global demand for non-toxic, long-lasting implants, bioceramics have emerged as a next-generation material. They promote osseointegration, reduce infection risks, and avoid immune rejection—crucial in orthopedic, maxillofacial, and dental surgeries.

Breakthroughs of Bioceramics in 2025

Indian and international researchers in 2025 made key strides in:

- 3D-printable magnesium-infused bio-ceramics for patient-specific implants.

- Injectable ceramic pastes to heal microfractures non-surgically, especially among elderly osteoporosis patients.

These breakthroughs reduce surgery time and enhance post-op recovery.

Recent Breakthrough: India and the World

Ceramics terms are not known to many researchers in India, primarily because academic and industrial engagement with ceramics has historically been very narrow. The subject has often been overlooked in biomedical engineering curricula, and very few specialized labs have focused on bioceramic development. In contrast, countries like the United States, Germany, and Japan have invested decades into advancing ceramic biomaterials for medical use, especially in dental, orthopedic, and spinal implants.

However, this gap is quickly narrowing. In India, the Sree Chitra Tirunal Institute for Medical Sciences and Technology (SCTIMST) has emerged as a national leader in bioceramic research, developing indigenous calcium phosphate and calcium sulfate-based grafts. With over 30 patents, SCTIMST’s breakthroughs in synthetic bone fillers and coatings are bringing affordable, world-class materials to Indian hospitals. Meanwhile, globally, researchers are now creating self-healing bioceramic scaffolds—using calcium polyphosphate microcapsules that release ions upon cracking to naturally repair microfractures. Another promising innovation involves coating scaffolds with probiotic biofilms, such as Lactobacillus acidophilus, to enhance bone healing through microbiome interaction, angiogenesis, and immune regulation.

These global and local innovations signal a promising future where India may become a manufacturing and R&D hub for sustainable and high-performance bioceramic solutions.

Real-World Applications

Bio-ceramics are currently used in:

- 🦷 Tooth roots and dental crowns (zirconia)

- 🦿Hip and knee replacements (alumina and zirconia components)

- 🦴 Bone grafts and void fillers

- 💀Facial reconstruction surgeries

- Spinal fusion implants

India’s leading hospitals now use hydroxyapatite coatings on titanium implants for better bone bonding and reduced complications.

Drawbacks

Despite their advantages, bioceramics have notable limitations:

| Drawback | Explanation |

|---|---|

| Brittleness | Poor tensile and flexural strength; prone to fracture. |

| Machining Difficulty | Hard to shape, polish, or drill without expensive equipment. |

| Limited Load-Bearing Use | Not ideal for high-impact joints unless combined with metal. |

| High Production Cost | Customization and precision manufacturing are costly. |

Sustainability Angle: Green Bio-ceramics

Researchers are exploring bio-derived ceramics using eggshells, seashells, and bamboo ash. These approaches reduce environmental impact and may offer cost-effective alternatives in the long run.

Market Size & Growth: Bio-ceramics vs. Metal Implants

| Segment | 2023 Market Size | 2025 (Est.) | CAGR (2023–2028) |

|---|---|---|---|

| Bioceramics | $4.14–7.67 B* | $4.43–7.9 B** | 6.9–9.5%*** |

| Metal Implants | $26.05 B† | $32.47 B† | ~3.8–5.1%†† |

• * MarketWatch: Global medical/advanced ceramics expected to reach $29.93 B by 2032, with CAGR 6.2% from 2025. • TheBusinessResearchCompany & Grand View: ceramics $4.14 B → $4.43 B at 6.9% CAGR; Market Trends section estimated $6.2 B → $7.9 B with 9.5% CAGR as a plausible midpoint. †† Metal implant CAGR widely reported between 4.5–5.1% via Grand View & WHO industry sources

While metal implants dominate by volume and value, bio-ceramics are growing faster due to increased demand for non-reactive, lightweight, and long-lasting materials in joint and dental replacements.

Market Drivers for Bio-ceramics:

- Aging populations requiring joint replacements

- Rise in dental restoration surgeries worldwide

- Growing concerns over metal allergies and implant corrosion

- Advancements in 3D printing of ceramics

- Government focus on biocompatible and safer medical devices

In India, demand is rising in both public and private sectors, especially with Make in India initiatives encouraging local production of bio-implants.

Future Outlook

According to market projections, bio-ceramics could account for 15–20% of the global orthopedic and dental implant market, driven by rising demand in Asia-Pacific and Europe. The future of the field is likely to be shaped by hybrid implants—particularly those combining ceramic coatings with titanium cores—which are increasingly viewed as the next-generation clinical standard for durability and biocompatibility.

Bio-ceramics vs Metal Implants: Which One is Better?

| Feature | Bioceramics | Metal Implants |

|---|---|---|

| Biocompatibility | Excellent (especially hydroxyapatite) | Varies (Titanium = good, others less) |

| Corrosion | No corrosion | Prone to oxidation and leaching |

| Mechanical Strength | Lower (brittle) | High load-bearing capacity |

| Weight | Lightweight | Heavier (esp. stainless steel) |

| Cost | Higher per unit, lower long-term failure | Moderate upfront, may need replacement |

| Bioactivity | Possible (bioactive ceramics) | Generally inert |

When it comes to medical implants—especially for bones, joints, and dental applications—bio-ceramics and metal implants each have distinct advantages and limitations.

In terms of biocompatibility, bio-ceramics—particularly those made from hydroxyapatite—excel due to their close resemblance to the mineral content of natural bone. Metals like titanium also offer good biocompatibility, but other alloys may pose allergic or inflammatory risks in sensitive individuals.

One of the major strengths of bio-ceramics is that they are completely corrosion-free and chemically inert, unlike metals, which are prone to oxidation and ion leaching over time. This makes bio-ceramics particularly valuable in long-term or sensitive applications, such as dental implants or spinal fusion.

However, metals still outperform bio-ceramics in terms of mechanical strength. While bio-ceramics are strong in compression, they are brittle and may fracture under tensile or flexural stress. Metals, especially titanium and stainless steel, remain the gold standard for load-bearing applications like hip and knee joints due to their high strength and flexibility.

Bio-ceramics are also lighter in weight, which can improve patient comfort and reduce the stress on surrounding tissues. Metals, particularly stainless steel, tend to be heavier, though this can sometimes aid stability in orthopedic settings.

From a cost perspective, bioceramic components are often more expensive upfront due to complex manufacturing processes, but they may lead to lower failure or revision rates in the long run. Metal implants are generally more affordable initially, but depending on the material, they may corrode or require replacement over time.

Finally, bioactivity—the ability to bond with bone tissue—is a key area where bio-ceramics shine. Many of them are bioactive or osteoconductive, promoting natural bone integration. Metals, by contrast, are mostly inert and may require surface coatings to improve bone bonding.

In summary, bio-ceramics offer superior biocompatibility and chemical stability, making them ideal for specific applications, especially in patients with metal sensitivity or in low-impact areas. Metals, however, continue to dominate load-bearing surgeries due to their unmatched mechanical strength.

Frequently Asked Questions about Bioceramics

1. What are bioceramics used for?

Bioceramics are used in medical and dental applications such as dental implants, bone grafts, and joint replacements. Their high biocompatibility and long-term durability make them ideal for integration with human tissue.

2. Are bioceramics better than metals?

Bioceramics are biologically safer and resistant to corrosion, but they lack the mechanical strength of metals. They are ideal for non-load-bearing roles or when used in hybrid designs with metals.

3. How big is the bioceramics market?

The global bioceramics market is valued at around $7.9 billion in 2025 and is projected to exceed $10 billion by 2028, growing at a CAGR of 9–10%.

4. Are metal implants being replaced?

Not completely. While metals remain crucial for high-stress applications, bioceramics are increasingly used for low-stress and bio-sensitive procedures due to their inert nature.

5. Can bioceramics be made in India?

Yes. Indian research institutions like IISc and IITs, along with biotech startups, are developing cost-effective, indigenous bioceramics for various medical uses.

Final Thoughts

As the global demand shifts toward personalized, safer, and longer-lasting medical implants, bioceramics are positioning themselves as the material of the future. While they may not fully replace metals, they’re increasingly being used alongside them — creating hybrid solutions that combine strength with biocompatibility.

With ongoing breakthroughs, India has the opportunity to become a global hub for affordable and sustainable bioceramic technologies in healthcare.

Subscribe and follow us for the latest updates on news, government schemes, job alerts, scholarships, and more.